-

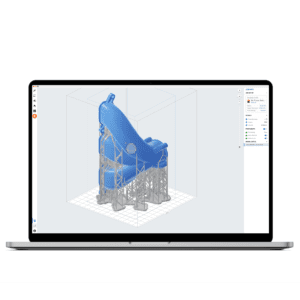

Form 4BL

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesForm 4BL is a blazing fast large-format dental 3D printer that offers the most diverse materials library for dentistry and orthodontics.

Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4BL ecosystem. Form 4BL’s speed is driven by Formlabs’ new Low Force Display™ Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display. Together they cure each layer of resin rapidly — regardless of part size or quantity. With consistent surface accuracy, models, appliances, and prosthetics will fit every time. -

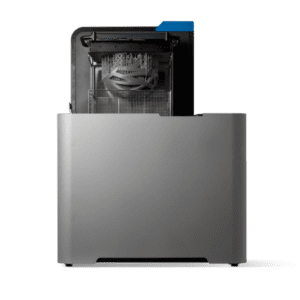

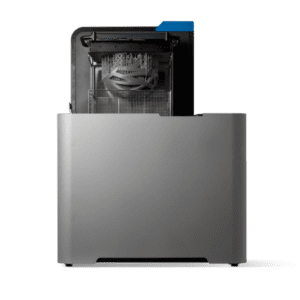

Form Auto

3D Scanning / Printing, Automation, Dental, Imaging, New ProductsAutomation Hardware for Your Dental 3D Printer

Form Auto is a hardware extension for the Form 3B/3B+ that automatically removes finished parts from the Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 printing with no downtime. Always available, always ready, and always printing. Your Form 3B+ Just Became the Most Productive Tool in Your Lab Scale capacity with autonomous production and produce parts faster and more affordably than ever with Form Auto, Fleet Control, and the High Volume Resin System by Formlabs. Skyrocket Your Ability to Produce High-Quality and Affordable Models Quickly, with Automated 24/7 3D Printing Reduce cost per part with autonomous 24/7 printing on your Form 3/3+ 3D printer. Form Auto runs back-to-back prints which redefine your idea of throughput: Start Scaling Your Orthodontic and Restorative Model Production Now. Work more efficiently and redefine production capacity in your 3D printing workflow with Formlabs Automation Ecosystem including Form Auto, Fleet Control, and the High Volume Resin System. Scale your dental model production without increasing printer management complexity. Hit send from anywhere and Formlabs Automation Ecosystem will take care of the rest. Minimize Cost Per Part with Labor Savings Up to 80%*. Form Auto condenses multi-operator shifts and works overtime so you don’t have to. Run printers unattended over the weekend to reduce turnaround times and deliver high-quality parts on-time to patients. Instantly automate your printers without additional training. Form Auto works with any Form 3B/3B+ 3D printer out in the field or purchased today, so you can level up your production at any time. Challenge the idea of your lab’s limitations, while minimizing staff printer interactions and costs. * Calculation based on dental arches printed in Draft Resin at 200µm. Effortless 24/7 Dental 3D Printing, with No Interaction Required. Before Form Auto, every completed part required manual removal from the build platform before post-processing. Form Auto fully automates part removal by leveraging Formlabs patented Quick Release Technology with Build Platform 2. Collected parts are placed in a UV-safe container for seamless batch transfer to the Form Wash. Tackle rush prints easily and from anywhere. Re-order your fleet's queue no matter where you are to make sure parts are printed ASAP at the lab. Monitor and review finished prints remotely via images and videos in Fleet Control. An onboard camera saves a record of each print by capturing images and videos of each job. Increase Your Lab’s Printing Capacity Today Form Auto will ensure your printer is always ready for whatever’s next. With the capacity to scale to any workload, your fleet has never been more powerful. https://www.youtube.com/watch?v=ic-geA7WWlI Learn more about Form Auto -

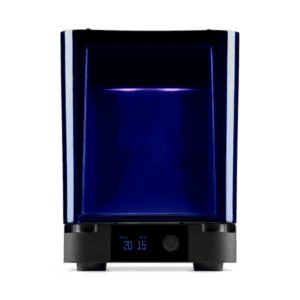

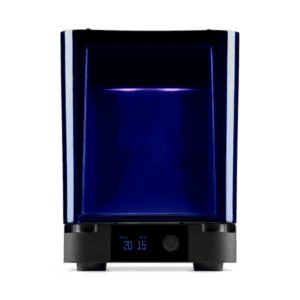

Form Cure

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. Post-Curing, Simplified Our automated post-curing solution, Form Cure, includes custom settings that maximize material performance, ensure consistent dimensional accuracy, and meet biocompatibility requirements for each Formlabs material with just the push of a button. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Cure L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk -

Form Wash

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. An Automated, Thorough Rinse Form Wash agitates isopropyl alcohol (IPA) to perfectly clean your parts, then raises them to air dry once finished. Simply set the appropriate time and let Form Wash get to work. Once washing completes, parts air dry and are ready when you are. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Wash (2nd Generation)

3D Scanning / Printing, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesAutomate Cleaning With Form Wash

Form Wash automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook and cranny perfectly clean, automatically for the appropriate time. When washing completes, the Form Wash automatically raises parts out of the IPA so they can air dry. https://youtu.be/4MIWA9_TLfo -

Form Wash L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk -

Formlabs Nylon 12 Tough Powder

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesNylon 12 Tough Powder offers the best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber.

Print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength. Nylon 12 Tough Powder should not be printed with virgin powder. Learn more about Powder Aging. Compatible with: Fuse 1+ 30W -

Formlabs Nylon 12 White Powder

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesNylon 12 White Powder combines all of the great qualities of the general purpose and biocompatible Nylon 12 Powder with the customisability of white parts.

Create functional prototypes and end-use customer-facing parts that can be easily dyed to match brand aesthetics as well as medical devices and models with high contrast and detail. Nylon 12 White Powder should not be printed with virgin powder or without retuning the print bed temperature. Learn more about Powder Aging and Bed Temperature Tuning. For best results, print Nylon 12 White Powder with inert atmospheric control. Compatible with: Fuse 1+ 30W -

Formlabs Software Dashboard

3D Scanning / Printing, Dental, Imaging, New Products, SoftwareFormlabs Software

3D Printing Setup, Management, and Monitoring Made SimpleStay informed wherever you are. Your Printer Dashboard allows you to access your printer from anywhere.

Be Notified Receive alerts when a print starts, finishes, or when a printer requires attention. Stay Organized Manage and watch multiple printers remotely as you scale your operation. Keep Track Monitor resin levels and tank usage, and know before it’s time to restock consumables. -

Formlabs Software Fleet Control

3D Scanning / Printing, Dental, Imaging, New Products, SoftwareFormlabs Software

3D Printing Setup, Management, and Monitoring Made SimpleFleet Control

Simplify how you manage a fleet of Formlabs SLA 3D printers and a group of users with advanced fleet management. Activate new features within Formlabs’ PreForm and Dashboard software to start automating and optimizing your workflow for maximum fleet productivity. Simplify Multi-Printer Management Let Fleet Control serve as the manager for your Printer Group to streamline your workflow and increase productivity. Collaborate in one centralized Dashboard queue where multiple users can add, duplicate and prioritize prints at any time across a fleet of 3D printers, wherever they may be. Improve Fleet-Wide Productivity With the Automatic Assigning of Prints Optimize production across your fleet. When a member from your team uploads a print to Dashboard, Fleet Control will automatically assign a printer for the print based on common consumables. Consolidate Real-Time Information and Improve Printer Group Oversight Receive live updates and notifications about your prints, printers, and Printer Groups. Take Control of User Permissions and Team Visibility Increase visibility over your team and into your printer fleet by setting admin and member access levels within Printer Groups. Keep Your Fleet Up-to-Date Update all your printers to the latest firmware automatically or select a recent version and apply it to printers from your list. Maximize the Health of Your Printer Group Gain visibility into key statistics about a printer fleet’s health. Review key statistics to maximize utilization and monitor potential maintenance. Maximize Your Printer Fleet’s Throughput with 24/7 Production Reach new levels of productivity with a fully automated fleet of Form 3+ 3D printers that you can operate from anywhere. Skyrocket your ability to produce high-quality, affordable parts with 24/7 back-to-back production with Formlabs’ Automation Ecosystem: Form Auto, Fleet Control, and the High Volume Resin System. -

Formlabs Software PreForm

3D Scanning / Printing, Dental, Imaging, New Products, SoftwareFormlabs Software

3D Printing Setup, Management, and Monitoring Made SimpleOptimize Your Print Processes in PreForm

Design your model in standard CAD software, then import the STL or OBJ file into our print preparation software, PreForm. Get your model ready in minutes, upload to your printer, and let it build. Fast, reliable printing in one click PreForm’s automatic algorithms set up your print’s layout, orientation, and supports, so anyone on your team can print successfully without specialized training. -

Vatech 2D PaX-i Insight

Dental, Extra Oral Xrays 2D, Imaging, VatechDEPTH ADDED PANORAMA, PaX-i Insight

PaX-i Insight is a step forward technology from the traditional way of acquiring images along a single focal layer. PaX-i Insight serves multi layers which add depth to panoramic image. Insight simply means more! Find more information from panoramic image. PaX-i Insight allows you to have insight with the depth information. It improves your diagnostic accuracy with increased treatment planning and patient satisfaction. Insight Pan- The next evolutionary step forward in panoramic imaging with Insight Pan

- 1.9 second acquisition time produces

- superb image quality Reduced motion artifacts and faster workflow

- Powerful diagnostic value with Insight feature

- Complete solution for consultation

- Easy to learn, easy to use

-

Vatech 2D PaX-i Plus

Dental, Extra Oral Xrays 3D, Imaging, VatechTHE ADVANCED IMAGING SOLUTION FOR ACCURATE DENTAL DIAGNOSIS

The PaX-i Plus provides the most precise and high quality panoramic images by combining image processing and accumulated experience in dental imaging from Vatech. This will increase your diagnostic accuracy for improved treatment planning and patient satisfaction.MINIMIZE MOTION ARTIFACTS WITH RAPID CEPH TECHNOLOGY

The next step in cephalometric technology, Vatech's new Rapid Ceph minimizes motion artifacts and enables faster diagnostic workflow while providing the highest quality digital images. GREAT CLINICAL CARE WITH RAPID CEPH TECHNOLOGY -

Vatech 3D A9

Extra Oral Xrays 3D, Imaging, VatechA NEW DIMENSION BEYOND YOUR EXPECTATIONS, A9

The Vatech A9 provides the most precise and high quality panoramic images by combining image processing and accumulated experience in dental imaging from Vatech. This will increase your diagnostic accuracy for improved treatment planning and patient satisfaction -

Vatech 3D Green 18

Dental, Extra Oral Xrays 3D, Imaging, VatechGREEN INNOVATION FOR THE NEXT GENERATION, Green18

Green18 is an advanced 4-in-1 digital X-ray imaging system that incorporates PANO, CEPH (Optional), CBCT and MODEL Scan. It provides high quality images with lower radiation by combining imaging processing and accumulated experience in dental imaging from VATECH. This will improve your diagnostic accuracy with increased treatment planning and patient satisfaction.

Shop

Home » Shop