Enable your productivity in an easy way!

These products will surely boost the efficiency of your practice.

-

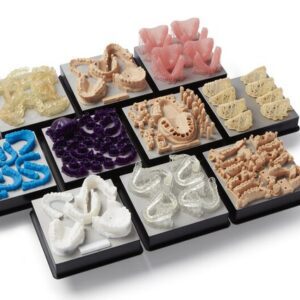

Formlabs Dental Resins

3D Scanning / Printing, Consumables, Consumables, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing & ConsumablesHigh-Accuracy 3D Printing Materials for Dental Labs and Practices

Bring production in-house or improve existing workflows with industry-leading Formlabs 3D printers. Our Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.Please contact us for information on specific FormLabs Dental Resins.

-

Durr Hygoclave 40

Autoclaves, Dental, Durr, Medical, New Products, Sterilisation & Maintenance, Steriliser ProductsThe new pacesetter in the hygiene cycle

In order for sterilisation equipment to really make a difference in demanding day-to-day practice, it needs to deliver outstanding strengths in all key areas. This includes ensuring reliable sterilisation results and offering a combination of genuinely user-friendly operation, exceptional efficiency and high reliability. With the Class B Hygoclave 40, DÜRR DENTAL meets the highest professional requirements for sterilisation cycles and thus provides a cost-effective basis for successful day-to-day working. Intuitive interface With a high-resolution 5" colour touch display featuring an intuitive user interface, it couldn't be easier to use and operate your Hygoclave 40. Seamless documentation All sterilisation records and the cycle information are automatically saved in the internal memory of the unit. The records can be easily downloaded and opened as PDF files, with flexible options to do this via USB, Ethernet or Wi-Fi. In addition, the records can also be printed out using the optionally available external printer. Integrated filling pump Maximum flexibility for filling the fresh water container thanks to the additional connections on the front and the integrated filling pump. https://youtu.be/wlnh4xcPB60 Take a look at the Hygoclave 40 / 40 Plus Brochure -

Durr Hygoclave 40 Plus

Autoclaves, Dental, Durr, Medical, New Products, Sterilisation & Maintenance, Steriliser ProductsThe new pacesetter in the hygiene cycle

In order for sterilisation equipment to really make a difference in demanding day-to-day practice, it needs to deliver outstanding strengths in all key areas. This includes ensuring reliable sterilisation results and offering a combination of genuinely user-friendly operation, exceptional efficiency and high reliability. With the Class B Hygoclave 40, DÜRR DENTAL meets the highest professional requirements for sterilisation cycles and thus provides a cost-effective basis for successful day-to-day working. Intuitive interface With a high-resolution 5" colour touch display featuring an intuitive user interface, it couldn't be easier to use and operate your Hygoclave 40. Seamless documentation All sterilisation records and the cycle information are automatically saved in the internal memory of the unit. The records can be easily downloaded and opened as PDF files, with flexible options to do this via USB, Ethernet or Wi-Fi. In addition, the records can also be printed out using the optionally available external printer. Integrated filling pump Maximum flexibility for filling the fresh water container thanks to the additional connections on the front and the integrated filling pump. https://youtu.be/wlnh4xcPB60 Take a look at the Hygoclave 40 / 40 Plus Brochure -

Durr Hygoclave 50

Autoclaves, Dental, Durr, Medical, New Products, Sterilisation & Maintenance, Steriliser ProductsHygoclave 50. Hygiene is in our DNA.

With Hygoclave 50, Dürr Dental offers dental practices a professional Class B solution that combines impressive performance with a well thought-out operating concept – for maximum efficiency and exceptional user friendliness designed to cope effortlessly with tough day-to-day working environments. Robust stainless steel chamber Stainless steel and plastic are used across the board in the sterilisation process to prevent the the risk of highly corrosive demineralised water dissolving ions from the materials. Chemical reactions that could impair the sterilisation process are suppressed as a result. High-performance process control Regardless of the size of the dental practice, the required throughput or the structural conditions of the building: when it comes to fresh water supply, every practice has to go its own way. Hygoclave 50 has proved itself to be a flexible partner capable of offering the perfect solution for any constellation. 1. Manual fresh water supply 2. Co1mbination with a water treatment system 3. Integrated pump Display With the intuitive operation of its graphical interface, the high-resolution 5" touch screen delivers comfortable standalone operation of all functions. Colour-coded icons on the home screen make for incredibly easy navigation and offer fast access to key functions and the integrated user management system. There, the most recently executed sterilisation and test cycles can be conveniently started via quick access or programme starts can be freely programmed. https://youtu.be/uv5wOpSlVsY Take a look at the Hygoclave 50 / 50 Plus Brochure -

Durr Hygoclave 50 Plus

Autoclaves, Dental, Durr, Medical, New Products, Sterilisation & Maintenance, Steriliser ProductsHygoclave 50. Hygiene is in our DNA.

With Hygoclave 50, Dürr Dental offers dental practices a professional Class B solution that combines impressive performance with a well thought-out operating concept – for maximum efficiency and exceptional user friendliness designed to cope effortlessly with tough day-to-day working environments. Robust stainless steel chamber Stainless steel and plastic are used across the board in the sterilisation process to prevent the the risk of highly corrosive demineralised water dissolving ions from the materials. Chemical reactions that could impair the sterilisation process are suppressed as a result. High-performance process control Regardless of the size of the dental practice, the required throughput or the structural conditions of the building: when it comes to fresh water supply, every practice has to go its own way. Hygoclave 50 has proved itself to be a flexible partner capable of offering the perfect solution for any constellation. 1. Manual fresh water supply 2. Co1mbination with a water treatment system 3. Integrated pump Display With the intuitive operation of its graphical interface, the high-resolution 5" touch screen delivers comfortable standalone operation of all functions. Colour-coded icons on the home screen make for incredibly easy navigation and offer fast access to key functions and the integrated user management system. There, the most recently executed sterilisation and test cycles can be conveniently started via quick access or programme starts can be freely programmed. https://youtu.be/uv5wOpSlVsY Take a look at the Hygoclave 50 / 50 Plus Brochure -

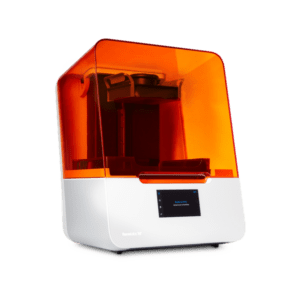

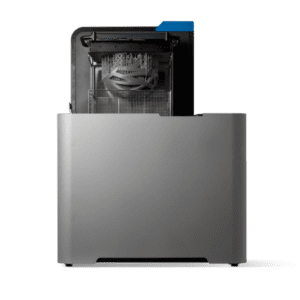

Form 3B+

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Most Trusted Dental 3D Printer

The Form 3B+ provides dental professionals with maximum performance and versatility with an easy workflow. 3D print a wide variety of dental applications in-house with minimal interaction and unrivaled print accuracy and surface finish.Fully Validated Workflows for the Practice and the Lab

The Formlabs Dental 3D printing ecosystem enables plug-and-play integration with your existing workflow for a seamless experience. The Form 3B+ is an all-encompassing digital workflow solution, including intuitive and innovative software, a resin portfolio for 10+ indications, including a wide variety of biocompatible materials, and simple, automated post-processing. No matter if you are ready to scale or engage for the first time in digital dentistry, the Form 3B+ is ready to produce high-quality parts you’ll be proud to deliver, without hassle, or prohibitive costs.Industry Leading Print Quality

The Form 3B+ is powered by our unique SLA printing process, delivering precise, unmatched surface finish and print accuracy across multiple dental applications when compared to other 3D printers. The Form 3B+ delivers: *Peace of Mind - Industry-leading print quality *Precise - Unmatched surface detail and finishing *Easy - Calibration free printingThe Easiest 3D Printer to Learn and Use

Bring dental dentistry to your practice or lab for the first time, or scale to dozens of machines, the Form 3B+ is ready to grow with your business. Your Form 3B+ comes with: One-hour personalized training call Mess-free material handling Start and track prints from anywhere with Remote Print and DashboardSimple, Low-Maintenance Resin Handling

The Form 3B+ Resin Tank lasts up to four months, reducing wasted resin and maintenance. Our cartridge system is designed to prevent spillage and keep your workspace clean, while minimizing resin waste at the same time. Spend less time cleaning your workspace and more time focusing on growing your business. After printing, use Form Wash and Form Cure streamline and automate rinsing and post-curing of prints. Clean - Spill-free resin dispense system Easy - Lightning fast and easy resin swap Efficient - Intelligent resin release systemThe Printer for Maximum Performance and Versatility

Produce a wide range of dental applications with our versatile printer and our dedicated dental resins, delivering high-performance parts with peace of mind through regulatory compliance and certified biocompatibility. https://www.youtube.com/watch?v=s94KgsbGmzc Learn more about Form 3B+ -

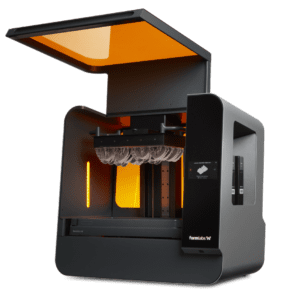

Form 3BL

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe New Standard for High Volume Dental 3D Printing

The Form 3BL is the large format dental 3D printer that raises the bar for dependable high-production dental 3D printing, designed to work day and night with minimal intervention.Maximum Productivity, Minimum Intervention

A build volume of 33.5 × 20 × 30 cm (13.2 × 7.9 × 11.8 in) maximizes throughput for every print job. Print up to 120 models in a day, with just a few printer interactions. A Robust 3D Printing Ecosystem The Form 3BL works full time so you don’t have to. Intuitive nesting software and automated post-processing options make custom manufacturing easy. Full Arch Ort1hodontic Model Grey Resin at 100 micron layer thickness Accuracy Range: ± 100 µm Surface in Accuracy Range: 94% ± 8% *Validation parts were printed using Grey Resin on Form 3BL printers. Results may vary. Cloud monitoring Remotely monitor and inspect your fleet of printers and track resin and tank usage over time with the online Dashboard.Status alerts

Enable SMS and email notifications to receive notifications when prints are completed or your printer needs attention.Automatic resin dispensing

Our automated resin system dispenses resin as parts print. The Form 3L holds two cartridges of resin to avoid mid-print interruptions.In-house repairs

The Light Processing Units, rollers, and optics window can be replaced in-house, so you don’t have to wait for a replacement printer if something goes wrong.Designed for Nonstop Throughout

The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention. A Team of Dental Experts Behind Formlabs Dental is a dedicated team of certified Dental Support Specialists who know exactly how to help when you need it. Our Dental Service Plan includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry. https://www.youtube.com/watch?v=rXk89kOGlmY Learn more about Form 3BL -

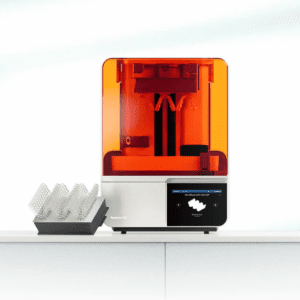

Form 4B Printer

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesBlazing Speed Meets Unmatched Accuracy

Unprecedented print speeds. Print a dental model every 49 seconds.Find more about Form 4B - Dental

https://www.youtube.com/watch?v=ch1T15LZeIU -

Form 4BL

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesForm 4BL is a blazing fast large-format dental 3D printer that offers the most diverse materials library for dentistry and orthodontics.

Create high-quality dental models and biocompatible appliances fast, with easy workflows, leading reliability, and stunning part quality using the Form 4BL ecosystem. Form 4BL’s speed is driven by Formlabs’ new Low Force Display™ Print Engine, a powerful combination of ultra-high power LEDs, collimating lenses, optical filters, and a robust liquid crystal display. Together they cure each layer of resin rapidly — regardless of part size or quantity. With consistent surface accuracy, models, appliances, and prosthetics will fit every time. -

Form Auto

3D Scanning / Printing, Automation, Dental, Imaging, New ProductsAutomation Hardware for Your Dental 3D Printer

Form Auto is a hardware extension for the Form 3B/3B+ that automatically removes finished parts from the Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 printing with no downtime. Always available, always ready, and always printing. Your Form 3B+ Just Became the Most Productive Tool in Your Lab Scale capacity with autonomous production and produce parts faster and more affordably than ever with Form Auto, Fleet Control, and the High Volume Resin System by Formlabs. Skyrocket Your Ability to Produce High-Quality and Affordable Models Quickly, with Automated 24/7 3D Printing Reduce cost per part with autonomous 24/7 printing on your Form 3/3+ 3D printer. Form Auto runs back-to-back prints which redefine your idea of throughput: Start Scaling Your Orthodontic and Restorative Model Production Now. Work more efficiently and redefine production capacity in your 3D printing workflow with Formlabs Automation Ecosystem including Form Auto, Fleet Control, and the High Volume Resin System. Scale your dental model production without increasing printer management complexity. Hit send from anywhere and Formlabs Automation Ecosystem will take care of the rest. Minimize Cost Per Part with Labor Savings Up to 80%*. Form Auto condenses multi-operator shifts and works overtime so you don’t have to. Run printers unattended over the weekend to reduce turnaround times and deliver high-quality parts on-time to patients. Instantly automate your printers without additional training. Form Auto works with any Form 3B/3B+ 3D printer out in the field or purchased today, so you can level up your production at any time. Challenge the idea of your lab’s limitations, while minimizing staff printer interactions and costs. * Calculation based on dental arches printed in Draft Resin at 200µm. Effortless 24/7 Dental 3D Printing, with No Interaction Required. Before Form Auto, every completed part required manual removal from the build platform before post-processing. Form Auto fully automates part removal by leveraging Formlabs patented Quick Release Technology with Build Platform 2. Collected parts are placed in a UV-safe container for seamless batch transfer to the Form Wash. Tackle rush prints easily and from anywhere. Re-order your fleet's queue no matter where you are to make sure parts are printed ASAP at the lab. Monitor and review finished prints remotely via images and videos in Fleet Control. An onboard camera saves a record of each print by capturing images and videos of each job. Increase Your Lab’s Printing Capacity Today Form Auto will ensure your printer is always ready for whatever’s next. With the capacity to scale to any workload, your fleet has never been more powerful. https://www.youtube.com/watch?v=ic-geA7WWlI Learn more about Form Auto -

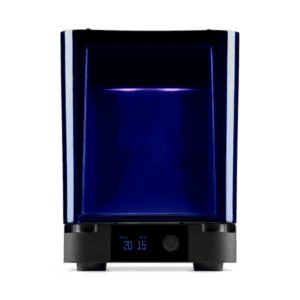

Form Cure

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. Post-Curing, Simplified Our automated post-curing solution, Form Cure, includes custom settings that maximize material performance, ensure consistent dimensional accuracy, and meet biocompatibility requirements for each Formlabs material with just the push of a button. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Cure L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk -

Form Wash

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesThe Perfect Finish, Every Time

Produce parts you’ll be proud to deliver with a tried and tested, start-to-finish dental 3D printing workflow that’s certified biocompatible. All stereolithography 3D prints require rinsing and post-curing to remove uncured resin and achieve peak quality. Our automated solutions make post-processing simple. An Automated, Thorough Rinse Form Wash agitates isopropyl alcohol (IPA) to perfectly clean your parts, then raises them to air dry once finished. Simply set the appropriate time and let Form Wash get to work. Once washing completes, parts air dry and are ready when you are. Less Effort, Higher Throughput Form Wash and Form Cure streamline your 3D printing process so you can consistently produce high-quality parts with less time and effort. https://www.youtube.com/watch?v=JpignAVCNl8 Learn more about Form Wash + Form Cure -

Form Wash (2nd Generation)

3D Scanning / Printing, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesAutomate Cleaning With Form Wash

Form Wash automatically cleans printed parts thoroughly and efficiently with IPA or alternative solvents. Keep parts directly on the Build Platform as you transition them from the printer to Form Wash, or remove parts and place them in the wash basket. Parts are precisely and thoroughly agitated in solvent with an impeller, getting every nook and cranny perfectly clean, automatically for the appropriate time. When washing completes, the Form Wash automatically raises parts out of the IPA so they can air dry. https://youtu.be/4MIWA9_TLfo -

Form Wash L

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesLess Effort, Higher Throughput

Streamline and automate the workflow for high-volume dental production with our large-format post-processing solutions. https://www.youtube.com/shorts/xcXqLNEHjTk -

Formlabs Nylon 12 Tough Powder

3D Scanning / Printing, Consumables, Dental, Formlabs Printing & Consumables, Imaging, New Products, Printing, Printing, Printing & ConsumablesNylon 12 Tough Powder offers the best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber.

Print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength. Nylon 12 Tough Powder should not be printed with virgin powder. Learn more about Powder Aging. Compatible with: Fuse 1+ 30W